Aerobic Granulation on:

[Wikipedia]

[Google]

[Amazon]

The biological treatment of wastewater in the

Nereda

. In September 2003, a first extensive pilot plant research was executed at STP Ede, the Netherlands with focus on obtaining stable granulation and biological nutrient removal. Following the positive outcome together with six Dutch Water Boards the parties decided to establish a Public-Private Partnership (PPP)- the National Nereda Research Progra

(NNOP)

to mature, further scale-up and implement several full-scale units. As part of this PPP extensive pilot tests have been executed between 2003 and 2010 at multiple sewage treatment plants. Currently more than 20 plants are running or under construction across 3 continents. * From the basis of the aerobic granular sludge but using a contention system for the granules, a sequencing batch biofilter granular reactor (SBBGR) with a volume of 3.1m3 was developed by IRSA (Istituto di Ricerca Sulle Acque, Italy). Different studies were carried out in this plant treating sewage at an Italian wastewater treatment plant. * The use of aerobic granules prepared in laboratory, as a starter culture, before adding in main system, is the base of the technology ARGUS ( Aerobic granules upgrade system) developed by EcoEngineering Ltd.. The granules are cultivated on-site in small bioreactors called propagators and fill up only 2 to 3% of the main bioreactor or fermentor (digestor) capacity. This system is being used in a pilot plant with a volume of 2.7 m3 located in one Hungarian pharmaceutical industry. * The Group of Environmental Engineering and Bioprocesses from the University of Santiago de Compostela is currently operating a 100 L pilot plant reactor. The feasibility study showed that the aerobic granular sludge technology seems very promising (de Bruin et al., 2004.de Bruin L.M.M., de Kreuk M.K., van der Roest H.F.R., Uijterlinde C. and van Loosdrecht M.C.M. (2004). Aerobic granular sludge technology: and alternative to activated sludge. ''Water Science and Technology'', Vol. 49, Nos. 11–12, pp. 1–7) Based on total annual costs a GSBR ( Granular sludge sequencing batch reactors) with pre-treatment and a GSBR with post-treatment proves to be more attractive than the reference activated sludge alternatives (6–16%). A sensitivity analysis shows that the GSBR technology is less sensitive to land price and more sensitive to rain water flow. Because of the high allowable volumetric load the footprint of the GSBR variants is only 25% compared to the references. However, the GSBR with only primary treatment cannot meet the present effluent standards for municipal wastewater, mainly because of exceeding the suspended solids effluent standard caused by washout of not well settleable biomass.

* EcoEngineering applied aerobic granulation process in three pharmaceutical industries, Krka d.d. Novo mesto Slovenia, Lek d.d. Lendava, Slovenia and Gedeon Richter Rt. Dorog, Hungary. Wastewater treatment plants are already running more than five years.

* EcoEngineering applied aerobic granulation process in three pharmaceutical industries, Krka d.d. Novo mesto Slovenia, Lek d.d. Lendava, Slovenia and Gedeon Richter Rt. Dorog, Hungary. Wastewater treatment plants are already running more than five years.

Nereda: The new Standard for Energy and Cost Effective Industrial and Municipal Wastewater treatment

''SKIW, Het National Water Symposium, May 2011''. * Water Sewage & Effluent (2010) 'Water Nymph' at Gansbaai, ''Water Sewage & Effluent, Water Management solutions for Africa, Volume 30 no.2, 2010, p50-p53''. * Gao D. Liu L. Liang H. Wu W.M. (2010), Aerobic granular sludge: characterization, mechanism of granulation and application to wastewater treatment, ''Critical reviews in Biotechnology'' * Dutch Water Sector (2012)

Commissioning Nereda at wwtp Epe: Wonder granule keeps its promise

* Kolver (2012)

Success at Gansbaai leads to construction of another Nereda plant

engineeringnews * Nadaba (2009)

Gansbaai wastewater project incorporates techno innovation

engineeringnews * Euronews (2012)

Dutch Investor cleans up water treatment

Royal HaskoningDHV-NEREDATUDELFT

– Delft University {{DEFAULTSORT:Aerobic Granulation Aquatic ecology Environmental engineering Environmental soil science Pollution control technologies Sewerage Water pollution

sewage treatment

Sewage treatment (or domestic wastewater treatment, municipal wastewater treatment) is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding envir ...

plant is often accomplished using conventional activated sludge

The activated sludge process is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using aeration and a biological floc composed of bacteria and protozoa. It uses air (or oxygen) and microorganisms ...

systems. These systems generally require large surface areas for treatment and biomass separation units due to the generally poor settling properties of the sludge

Sludge is a semi-solid slurry that can be produced from a range of industrial processes, from water treatment, wastewater treatment or on-site sanitation systems. For example, it can be produced as a settled suspension obtained from conventiona ...

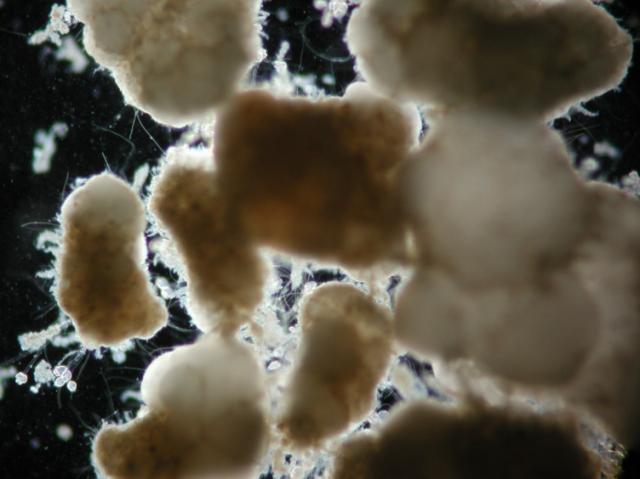

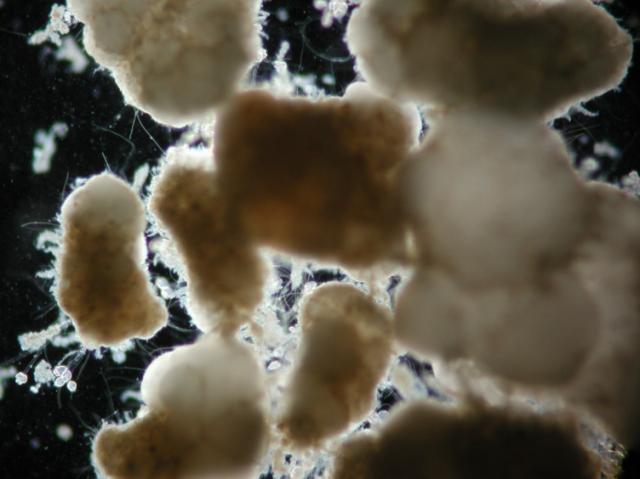

. Aerobic granules are a type of sludge that can self-immobilize flocs and microorganisms into spherical and strong compact structures. The advantages of aerobic granular sludge are excellent settleability, high biomass retention, simultaneous nutrient removal and tolerance to toxicity. Recent studies show that aerobic granular sludge treatment could be a potentially good method to treat high strength wastewaters with nutrients, toxic substances.

The aerobic granular sludge usually is cultivated in SBR (sequencing batch reactor

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment ...

) and applied successfully as a wastewater treatment for high strength wastewater, toxic wastewater and domestic wastewater. Compared with conventional aerobic granular processes for COD removal, current research focuses more on simultaneous nutrient removal, particularly COD, phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

and nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

, under pressure conditions, such as high salinity

Salinity () is the saltiness or amount of salt dissolved in a body of water, called saline water (see also soil salinity). It is usually measured in g/L or g/kg (grams of salt per liter/kilogram of water; the latter is dimensionless and equal ...

or thermophilic

A thermophile is an organism—a type of extremophile—that thrives at relatively high temperatures, between . Many thermophiles are archaea, though they can be bacteria or fungi. Thermophilic eubacteria are suggested to have been among the earl ...

condition.

In recent years, new technologies have been developed to improve settleability. The use of aerobic granular sludge technology is one of them.

Context

Proponents of aerobic granular sludge technology claim "it will play an important role as an innovative technology alternative to the present activated sludge process in industrial and municipal wastewater treatment in the near future" and that it "can be readily established and profitably used in activated sludge plants". However, in 2011 it was characterised as "not yet established as a large-scale application ... with limited and unpublished full-scale applications for municipal wastewater treatment."Aerobic granular biomass

The following definition differentiates an aerobic granule from a simple floc with relatively good settling properties and came out of discussions which took place at the ''1st IWA-Workshop Aerobic Granular Sludge'' in Munich (2004):Formation of aerobic granules

Granular sludge biomass is developed insequencing batch reactor

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment ...

s (SBR) and without carrier materials. These systems fulfil most of the requirements for their formation as:

: Feast – Famine regime: short feeding periods must be selected to create feast and famine periods (Beun et al. 1999Beun J.J., Hendriks A., Van Loosdrecht M.C.M., Morgenroth E., Wilderer P.A. and Heijnen J.J. (1999). Aerobic granulation in a sequencing batch reactor. ''Water Research, ''Vol. 33, No. 10, pp. 2283–2290.), characterized by the presence or absence of organic matter in the liquid media, respectively. With this feeding strategy the selection of the appropriate micro-organisms to form granules is achieved. When the substrate concentration in the bulk liquid is high, the granule-former organisms can store the organic matter in form of poly-''β''-hydroxybutyrate to be consumed in the famine period, giving an advantage over filamentous organisms. When an anaerobic feeding is applied this factor is enhanced, minimising the importance of short settling time and higher hydrodynamic forces.

: Short settling time: This hydraulic selection pressure on the microbial community allows the retention granular biomass inside the reactor while flocculent

Flocculation, in the field of chemistry, is a process by which colloidal particles come out of suspension to sediment under the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from pr ...

biomass is washed-out. (Qin et al. 2004)

: Hydrodynamic shear force : Evidences show that the application of high shear forces

In solid mechanics, shearing forces are unaligned forces acting on one part of a Rigid body, body in a specific direction, and another part of the body in the opposite direction. When the forces are collinear (aligned with each other), they ...

favours the formation of aerobic granules and the physical granule integrity. It was found that aerobic granules could be formed only above a threshold shear force value in terms of superficial upflow air velocity above 1.2 cm/s in a column SBR, and more regular, rounder, and more compact aerobic granules were developed at high hydrodynamic shear forces (Tay et al., 2001 ).

Granular activated sludge is also developed in flow-through reactors using the Hybrid Activated Sludge (HYBACS) process, comprising an attached-growth reactor with short retention time upstream of a suspended growth reactor. The attached bacteria in the first reactor, known as a SMART unit, are exposed to a constant high COD, triggering the expression of high concentrations of hydrolytic enzyme

Hydrolase is a class of enzyme that commonly perform as biochemical catalysts that use water to break a chemical bond, which typically results in dividing a larger molecule into smaller molecules. Some common examples of hydrolase enzymes are este ...

s in the EPS layer around the bacteria. The accelerated hydrolysis

Hydrolysis (; ) is any chemical reaction in which a molecule of water breaks one or more chemical bonds. The term is used broadly for substitution reaction, substitution, elimination reaction, elimination, and solvation reactions in which water ...

liberates soluble readily-degradable COD which promotes the formation of granular activated sludge.

Advantages

The development of biomass in the form of aerobic granules is being studied for its application in the removal oforganic matter

Organic matter, organic material, or natural organic matter refers to the large source of carbon-based compounds found within natural and engineered, terrestrial, and aquatic environments. It is matter composed of organic compounds that have c ...

, nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

and phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

compounds from wastewater.

Aerobic granules in an aerobic SBR present several advantages compared to conventional activated sludge process such as:

: Stability and flexibility: the SBR system can be adapted to fluctuating conditions with the ability to withstand shock and toxic loadings

: Low energy requirements: the aerobic granular sludge process has a higher aeration efficiency due to operation at increased height, while there are neither return sludge or nitrate recycle streams nor mixing and propulsion requirements

: Reduced footprint: The increase in biomass concentration that is possible because of the high settling velocity of the aerobic sludge granules and the absence of a final settler result in a significant reduction in the required footprint.

: Good biomass retention: higher biomass concentrations inside the reactor can be achieved, and higher substrate loading rates can be treated.

: Presence of aerobic and anoxic zones inside the granules: to perform simultaneously different biological processes in the same system (Beun et al. 1999 )

: Reduced investment and operational costs: the cost of running a wastewater treatment plant working with aerobic granular sludge can be reduced by at least 20% and space requirements can be reduced by as much as 75% (de Kreuk et al., 2004).

The HYBACS process has the additional benefit of being a flow-through process, thus avoiding the complexities of SBR systems. It is also readily applied to the upgrading of existing flow-through activated sludge processes, by installing the attached growth reactors upstream of the aeration tank. Upgrading to granular activated sludge process enables the capacity of an existing wastewater treatment plant to be doubled.

Treatment of industrial wastewater

Synthetic wastewater was used in most of the works carried out with aerobic granules. These works were mainly focused on the study of granules formation, stability and nutrient removal efficiencies under different operational conditions and their potential use to remove toxic compounds. The potential of this technology to treat industrial wastewater is under study, some of the results: * Arrojo et al. (2004) operated two reactors that were fed with industrial wastewater produced in a laboratory for analysis of dairy products (TotalCOD

Cod is the common name for the demersal fish genus '' Gadus'', belonging to the family Gadidae. Cod is also used as part of the common name for a number of other fish species, and one species that belongs to genus ''Gadus'' is commonly not call ...

: 1500–3000 mg/L; soluble COD: 300–1500 mg/L; total nitrogen: 50–200 mg/L). These authors applied organic and nitrogen loading rates up to 7 g COD/(L·d) and 0.7 g N/(L·d) obtaining removal efficiencies of 80%.

* Schwarzenbeck ''et al. ''(2004) treated malting wastewater which had a high content of particulate organic matter (0.9 g TSS/L). They found that particles with average diameters lower than 25–50 μm were removed at 80% efficiency, whereas particles bigger than 50 μm were only removed at 40% efficiency. These authors observed that the ability of aerobic granular sludge to remove particulate organic matter from the wastewaters was due to both incorporation into the biofilm

A biofilm comprises any syntrophic consortium of microorganisms in which cells stick to each other and often also to a surface. These adherent cells become embedded within a slimy extracellular matrix that is composed of extracellular ...

matrix and metabolic activity of protozoa

Protozoa (singular: protozoan or protozoon; alternative plural: protozoans) are a group of single-celled eukaryotes, either free-living or parasitic, that feed on organic matter such as other microorganisms or organic tissues and debris. Histo ...

population covering the surface of the granules.

* Cassidy and Belia (2005) obtained removal efficiencies for COD and P of 98% and for N and VSS over 97% operating a granular reactor fed with slaughterhouse wastewater (Total COD: 7685 mg/L; soluble COD: 5163 mg/L; TKN

The Kjeldahl method or Kjeldahl digestion () in analytical chemistry is a method for the quantitative determination of nitrogen contained in organic substances plus the nitrogen contained in the inorganic compounds ammonia and ammonium (NH3/NH4+) ...

: 1057 mg/L and VSS: 1520 mg/L). To obtain these high removal percentages, they operated the reactor at a DO saturation level of 40%, which is the optimal value predicted by Beun et al. (2001) for N removal, and with an anaerobic feeding period which helped to maintain the stability of the granules when the DO concentration was limited.

* Inizan ''et al. ''(2005) treated industrial wastewaters from pharmaceutical industry and observed that the suspended solids in the inlet wastewater were not removed in the reactor.

* Tsuneda et al. (2006), when treating wastewater from metal-refinery process (1.0–1.5 g NH4+-N/L and up to 22 g/L of sodium sulphate), removed a nitrogen loading rate of 1.0 kg-N/m3·d with an efficiency of 95% in a system containing autotrophic granules.

* Usmani et al. (2008) high superficial air velocity, a relatively short settling time of 5–30 min, a high ratio of height to diameter (H/D=20) of the reactor and optimum organic load facilitates the cultivation of regular compact and circular granules.

* Figueroa et al. (2008), treated wastewater from a fish canning industry. Applied OLR were up to 1.72 kg COD/(m3·d) with fully organic matter depletion. Ammonia nitrogen was removed via nitrification-denitrification up to 40% when nitrogen loading rates were of 0.18 kg N/(m3·d). The formation of mature aerobic granules occurred after 75 days of operation with 3.4 mm of diameter, SVI of 30 mL/g VSS and density around 60 g VSS/L-granule

*Farooqi et al. (2008), Wastewaters from fossil fuel refining, pharmaceuticals, and pesticides are the main sources of phenolic compounds. Those with more complex structures are often more toxic than the simple phenol

Phenol (also called carbolic acid) is an aromatic organic compound with the molecular formula . It is a white crystalline solid that is volatile. The molecule consists of a phenyl group () bonded to a hydroxy group (). Mildly acidic, it req ...

. This study was aimed at assessing the efficacy of granular sludge in UASB and SBR for the treatment of mixtures of phenolics compounds. The results indicates that anaerobic treatment by UASB and aerobic treatment by SBR can be successfully used for phenol/cresol mixture, representative of major substrates in chemical and petrochemical wastewater and the results shows proper acclimatization period is essential for the degradation of m – cresol and phenol. Moreover, SBR was found as a better alternative than UASB reactor as it is more efficient and higher concentration of m cresols can be successfully degraded.

*López-Palau et al. (2009), treated wastewater from a winery industry. The formation of granules was performed using a synthetic substrate and after 120 days of operation, synthetic media was replaced by real winery wastewater, with a COD loading of 6 kg COD/(m3·d).

*Dobbeleers "et al." (2017), treated wastewater from potato industry. Granulation was successful achieved and simultaneous nitrification/denitrification was possible by short cutting the nitrogen cycle.

*Caluwé "et al." (2017), Compared an aerobic feast/famine strategy and an anaerobic feast, aerobic famine strategy for the formation of aerobic granular sludge during the treatment of industrial petrochemical wastewater. Both strategies were successful.

Pilot research in aerobic granular sludge

Aerobic granulation technology for the application in wastewater treatment is widely developed at laboratory scales. The large-scale experience is growing rapidly and multiple institutions are making efforts to improve this technology: * Since 1999 Royal HaskoningDHV (former DHV Water), Delft University of technology (TUD), STW (Dutch Foundation for Applied Technology) and STOWA (Dutch Foundation for Applied Water Research) have been cooperating closely on the development of the aerobic granular sludge technologyNereda

. In September 2003, a first extensive pilot plant research was executed at STP Ede, the Netherlands with focus on obtaining stable granulation and biological nutrient removal. Following the positive outcome together with six Dutch Water Boards the parties decided to establish a Public-Private Partnership (PPP)- the National Nereda Research Progra

(NNOP)

to mature, further scale-up and implement several full-scale units. As part of this PPP extensive pilot tests have been executed between 2003 and 2010 at multiple sewage treatment plants. Currently more than 20 plants are running or under construction across 3 continents. * From the basis of the aerobic granular sludge but using a contention system for the granules, a sequencing batch biofilter granular reactor (SBBGR) with a volume of 3.1m3 was developed by IRSA (Istituto di Ricerca Sulle Acque, Italy). Different studies were carried out in this plant treating sewage at an Italian wastewater treatment plant. * The use of aerobic granules prepared in laboratory, as a starter culture, before adding in main system, is the base of the technology ARGUS ( Aerobic granules upgrade system) developed by EcoEngineering Ltd.. The granules are cultivated on-site in small bioreactors called propagators and fill up only 2 to 3% of the main bioreactor or fermentor (digestor) capacity. This system is being used in a pilot plant with a volume of 2.7 m3 located in one Hungarian pharmaceutical industry. * The Group of Environmental Engineering and Bioprocesses from the University of Santiago de Compostela is currently operating a 100 L pilot plant reactor. The feasibility study showed that the aerobic granular sludge technology seems very promising (de Bruin et al., 2004.de Bruin L.M.M., de Kreuk M.K., van der Roest H.F.R., Uijterlinde C. and van Loosdrecht M.C.M. (2004). Aerobic granular sludge technology: and alternative to activated sludge. ''Water Science and Technology'', Vol. 49, Nos. 11–12, pp. 1–7) Based on total annual costs a GSBR ( Granular sludge sequencing batch reactors) with pre-treatment and a GSBR with post-treatment proves to be more attractive than the reference activated sludge alternatives (6–16%). A sensitivity analysis shows that the GSBR technology is less sensitive to land price and more sensitive to rain water flow. Because of the high allowable volumetric load the footprint of the GSBR variants is only 25% compared to the references. However, the GSBR with only primary treatment cannot meet the present effluent standards for municipal wastewater, mainly because of exceeding the suspended solids effluent standard caused by washout of not well settleable biomass.

Full scale application

Aerobic granulation technology is already successfully applied for treatment of wastewater. * Since 2005, RoyalHaskoningDHV has implemented more than 20 full-scale aerobic granular sludge technology systems (Nereda) for the treatment of both industrial and municipal wastewater across 3 continents. One example is STP Epe, The Netherlands, with a capacity of 59.000 pe and 1,500 m3.h-1, being the first full-scale municipal Nereda in The Netherlands. Examples of the latest Nereda sewage treatment plants (2012–2013) include Wemmershoek- South Africa, Dinxperlo, Vroomshoop, Garmerwolde – The Netherlands. * EcoEngineering applied aerobic granulation process in three pharmaceutical industries, Krka d.d. Novo mesto Slovenia, Lek d.d. Lendava, Slovenia and Gedeon Richter Rt. Dorog, Hungary. Wastewater treatment plants are already running more than five years.

* EcoEngineering applied aerobic granulation process in three pharmaceutical industries, Krka d.d. Novo mesto Slovenia, Lek d.d. Lendava, Slovenia and Gedeon Richter Rt. Dorog, Hungary. Wastewater treatment plants are already running more than five years.

See also

*Agricultural wastewater treatment

Agricultural wastewater treatment is a farm management agenda for controlling pollution from confined animal operations and from surface runoff that may be contaminated by chemicals in fertilizer, pesticides, animal slurry, crop residues or i ...

* Effluent guidelines Effluent Guidelines (also referred to as Effluent Limitation Guidelines (ELGs)) are U.S. national standards for wastewater discharges to surface waters and publicly owned treatment works (POTW) (also called municipal sewage treatment plants). The Un ...

* Industrial wastewater treatment

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sa ...

* List of waste water treatment technologies

This page consists of a list of wastewater treatment technologies:

See also

*Agricultural wastewater treatment

*Industrial wastewater treatment

*List of solid waste treatment technologies

* Waste treatment technologies

*Water purification

*Sewa ...

* Sedimentation (water treatment)

Sedimentation is a physical water treatment process using gravity to remove suspension (chemistry), suspended solids from water. Solid particles entrained by the turbulence of moving water may be removed naturally by sedimentation in the still wate ...

* Water purification

Water purification is the process of removing undesirable chemicals, biological contaminants, suspended solids, and gases from water. The goal is to produce water that is fit for specific purposes. Most water is purified and disinfected for hu ...

* Sequencing batch reactor

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment ...

References

General references

* Van der Roest H., de Bruin B., van Dalen R., Uijterlinde C. (2012) Maakt Nereda-installatie Epe hooggespannen verwachtingen waar?, ''Vakblad H2O, nr.23, 2012, p30-p34''. * Giesen A., van Loosdrecht M.C.M., Niermans R. (2012) Aerobic granular biomass: the new standard for domestic and industrial wastewater treatment?, ''Water21, April 2012, p28-p30''. * Zilverentant A., de Bruin B., Giesen A. (2011Nereda: The new Standard for Energy and Cost Effective Industrial and Municipal Wastewater treatment

''SKIW, Het National Water Symposium, May 2011''. * Water Sewage & Effluent (2010) 'Water Nymph' at Gansbaai, ''Water Sewage & Effluent, Water Management solutions for Africa, Volume 30 no.2, 2010, p50-p53''. * Gao D. Liu L. Liang H. Wu W.M. (2010), Aerobic granular sludge: characterization, mechanism of granulation and application to wastewater treatment, ''Critical reviews in Biotechnology'' * Dutch Water Sector (2012)

Commissioning Nereda at wwtp Epe: Wonder granule keeps its promise

* Kolver (2012)

Success at Gansbaai leads to construction of another Nereda plant

engineeringnews * Nadaba (2009)

Gansbaai wastewater project incorporates techno innovation

engineeringnews * Euronews (2012)

Dutch Investor cleans up water treatment

External links

Royal HaskoningDHV-NEREDA

– Delft University {{DEFAULTSORT:Aerobic Granulation Aquatic ecology Environmental engineering Environmental soil science Pollution control technologies Sewerage Water pollution